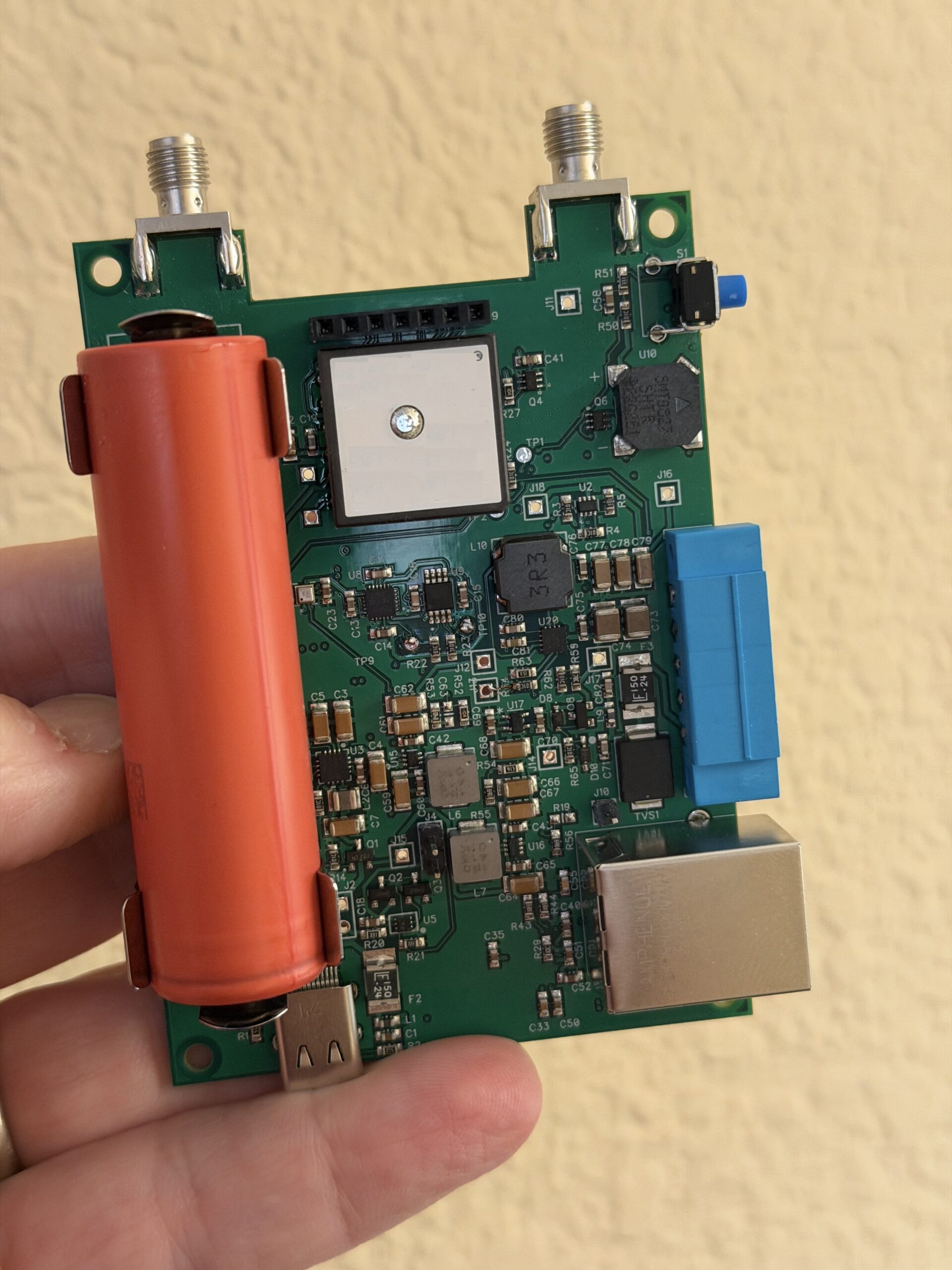

One distinct difference between the Falken EMS and other products is the way we connect engine probes and senders. Most EMS boxes require you to build a harness using DSub connectors. Now there’s nothing wrong with DSubs – we use them for all kinds of things – but for sensor connections we opted to use super-simple direct insert industrial connectors. These are spring clamp devices that allow you to just push a wire into a terminal to connect it. To release, press the little white release button and remove it.

Why is this advantageous for an EMS? Two reasons:

- The EMS has to accept several types and sizes of wire. Getting those wires into a DSub pin, and getting that pin into a DSub housing can be a pain.

- The probes and senders that connect to the EMS are, frankly, consumables: fly long enough and you will need to replace one or more.

The spring clamp connectors allow you to remove the one bad sender without having to disassemble a DSub and use one of those annoyingly fragile pin extraction tools to pop out the right wires. Just release the wire for the failed sender and insert the new one.

Ferrules

BUT… there is one requirement to use these connectors. You must attach a ferrule (pronounced like “feral”) to the end of the wire. A ferrule is a small metal band that is crimped onto the end of the wire to hold strands together and to stiffen the end. A ferrule makes it much easier to insert the wire tip into the EMS terminal. The crimping process creates corrugations (little valleys) in the surface that allow the spring connector to grip it better. Unlike tinning the end of the wire with solder, the ferrule doesn’t result in a brittle point where the wire can work harden and break. The crimping tools are cheap and readily available online. The ferrule bands themselves only cost a few cents.

Ferrules come in two types: insulated and non-insulated. The insulated types have a small plastic “boot” that goes over the wire to cover the junction between the stripped and unstripped part. Insulated ferrules are great for use with lever nuts (see below) but are problematic when working with the EMS. The boot can prevent the wire from inserting far enough into the connector for the spring jaws to hold it properly. For EMS connections we suggest using the 22 gauge non-insulated ferrules like this.

You generally want to use 10 mm ferrules, which are long enough to properly seat in the spring connector. You can get 1000 of them for about $12 from Ferrules Direct. Amazon also offers ferrule kits that include hundreds or thousands of ferrules and a crimping tool for less than $30. Note that most of these kits only include insulated ferrules. You can use them with the EMS, but you will want to carefully remove the insulating boot with a sharp shop knife.

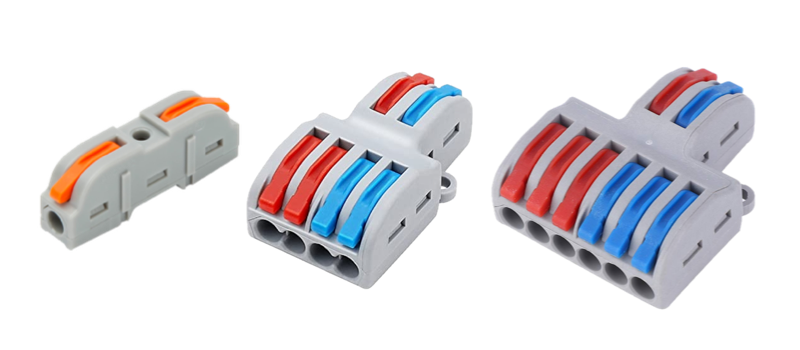

Lever Nuts

Insulated ferrules do have a place in aircraft wiring. They work perfectly with small gauge “lever nuts” – a safe and convenient way of connecting wires. Like our EMS spring clip connectors, lever nuts are “normally closed” spring clamp devices – the metal used for each clamp is structured to grip a wire. The lever allows you to open the “jaws” of the clamp to insert a wire. Releasing the lever allows the jaws to close. These are better than ring terminals (no screw to back out) and better than tab terminals (no crimp joint to wear harden and crack). We’ve been using them for several years – at first just for CAN bus connections but more recently for power – with no issues or failures.

I’m going to guess that this is a bit controversial. Aircraft are notorious for stressing components that work just fine in other applications. That said, we’ve done quite a bit of testing and so far have seen no evidence that vibration and other aircraft-specific factors result in wear or damage. Lever nuts started out in the electrical wiring world as a replacement for traditional wire nuts, so organizations like UL and NEMA have put them through extensive testing. They’re commonly used today to wire homes and offices all over the world. I would not use them for high current connections or outside of the cabin (they’re not weatherproof) but for data and low power connections they’re great.

One of their best features: lever nuts come in many configurations. There are one-to-one connectors that serve as a basic splice. There are two-to-six connectors that allow you run power and ground to three devices (we use these on our testbed RV-6A to power the FlightDock, FlightBar, and iPad charger). The two-to-four connectors are great for building CAN bus drops.

As with the EMS connectors, I highly recommend using a ferrule. (More than that: I wouldn’t use these connectors without using ferrules.) Most of the low power wiring in the aircraft is 22 gauge, and a 22 gauge insulated ferrule works perfectly, with the insulating boot fitting into the connector housing. The crimp bands on the ferrule make for an extremely strong connection.

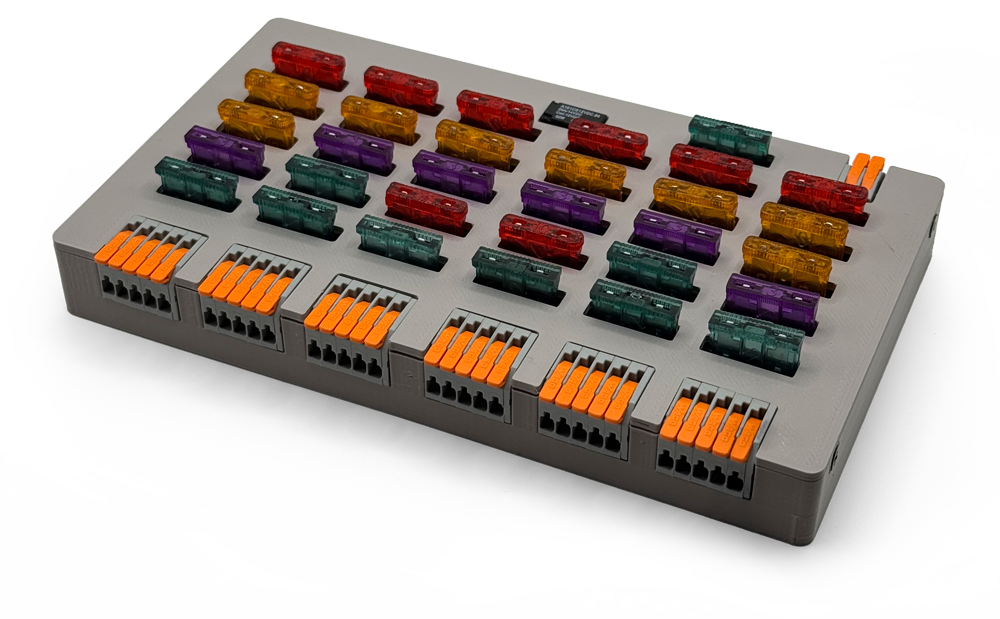

Lever Nuts In Action

A few months ago we announced BusBox, a new power distribution system that puts 30 circuits into a 6″ x 4″ package. We could have used tab connections or screw terminals but opted to go with the board-mount version of Wago lever nuts (properly “lever terminals” in this scenario) for the 30 load connections. BusBox supports loads of up to 10 amps per circuit and a total standing (constant) load of 30 amps. We did extensive testing, including a long term overload test, and found that the lever terminals were able to easily take the abuse. While there’s nothing really revolutionary about a fuse box, we’re fairly sure that BusBox will quickly become popular in the homebuilding community because of how easy it is to use. Lever terminals are a huge part of that appeal.

Things change slowly in the general aviation world. One of the joys of experimental aviation is being able to try out new and innovative ways of making things work. Lever nuts and ferrules aren’t the answer for every wiring situation, but they’re another good tool that makes building and maintaining an aircraft a little easier.